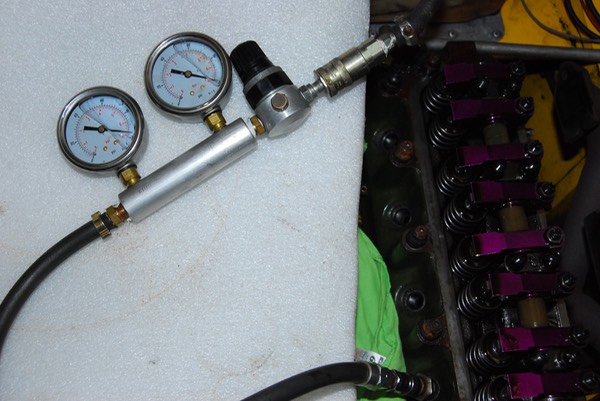

This test enables the sealing ability of the combustion chamber to be determined. The leakdown testing device concists of two pressure gauges with a 1mm hole in the line between them, pressure is applied to the inlet and the outlet is connected to the combustion chamber on its firing position ie both valves shut. The vehicle will need to be in gear with the handbrake on and wheels chocked to avoid the vehicle moving! If the sealing qualities are perfect the second gauge will show the same as the first as the 1mm hole will allow the pressures to balance, if the sealing qualities are poor the 1mm hole will not be able to flow enough air to keep up with demand and so the second reading will be low.

The following picture shows a leakdown test being performed on a good cylinder. The first gauge has been set at 100psi and the second gauge is reading 97psi. A compression test had been carried proir to this test showing cylinder 2 to be lower than the rest.

On the second cylinder the second gauge read 76psi indicating a problem, air could be heard exiting the adjacent plug hole, the ports on this engine are of the siamese type, as cylinder 3 readings were better this would indicate that the exhaust valve on Cylinder 2 is not sealing well. The inlet and exhaust manifolds can be removed and a liquid such as WD40 applied to the back of the valves to visually see if they are leaking. If the piston rings are worn air can be heard escaping past them which will pressurise the crankcase and can be heard exiting any breathers or the dipstick hole.

Here the head has been removed, a plate and gasket is bolted in place to enable pressure to be applied to the ports, again WD40 will show any leaks from the valves. Also the valve guides can be checked.

Here 20psi applied shows foaming around the valve but directly between the valves on cylinder 2 the leak was great enough to be felt by hand several inces away!

The problem can be rectified and rechecked before reassembly.